GLOZINC-AL Wire (Zinc-Aluminum Wire)

Description

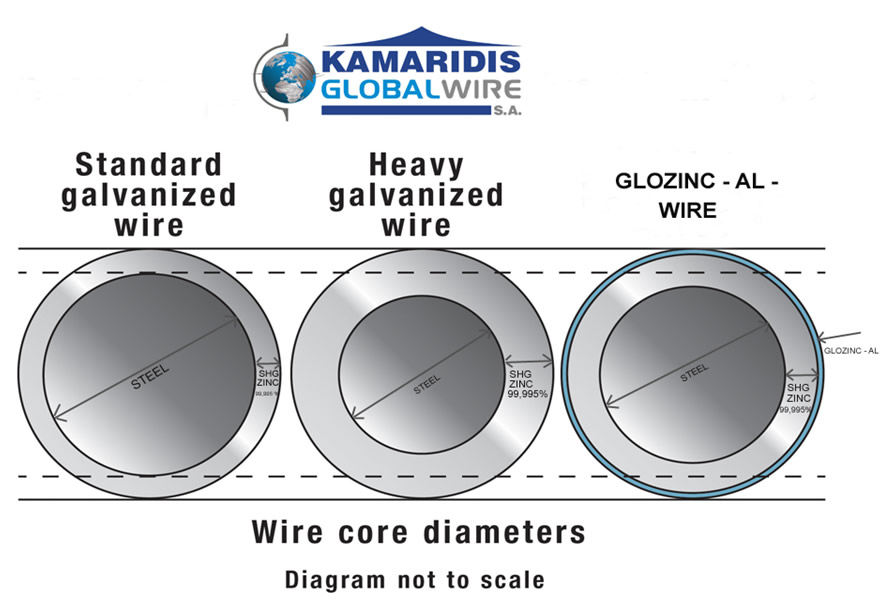

Glozinc-Al (Global Wire Zinc Aluminum) Wire is actually a special alloy galvanized wire also named as Zn-Al-Alloy Coating Iron Wire.

We offer a 95% Zinc + 5% Aluminum alloy Wire that shows an excellent performance in terms of resistance in corrosion and also durability over the years. The coating offers all the benefits of galvanized wire including its galvanic properties plus the corrosion resistance properties of aluminum.

Glozinc-Al wire features high tensile strength, small tolerance, Shiny surface, good corrosion prevention.

Properties & Advantages

- Excellent corrosion resistance which means 2-3 times better than Zn for the same coating weight.

- Cathodic protection better than with Zn.

- Good corrosion resistance maintained at welding spots.

- Stress relieving at 250 °C for 30min.

- Grey patina

- Ductility = easy deformation

- Low friction

- High- temperature performance compared to zinc coating.

- Exposure up to 350°C has no negative impact on the Glozinc-Al wire

Applications

Glozinc-Al wire has been designed as a better alternative to Zn coatings. It is a cost effective alternative for post-coated wire products.

Used in wire mesh, artware, metal hose, binding for agriculture and construction

- Wire for welded and woven gabions.

- Wire for welded panels.

- Wire for woven and welded fences.

- Wire for cages (chicken batteries, mink cages)

- Vineyard wire.

- Tensioning wire.

- Wire for anti-hail netting.

- Safety or protection mesh.

- Wire for slate hooks.

- Wires for agricultural use like sheep fence, reindeer fence.

- Gun nails

Technical Characteristics

|

GLOZINC-AL WIRE |

|

|

RAW MATERIAL QUALITY |

Wire rod SAE 1006 & SAE 1008 |

|

DIAMETER |

From Φ1,60 mm to Φ5,00 mm |

|

PACKAGING - WEIGHT |

Coils weighing up to 1000 kg |

|

DIMENSIONS, OUT-OF-ROUNDNESS, TOLERANCE |

According to ΕΝ 10218-02 |

Technical Data Tables

|

GLOZINC-AL WIRE |

||||

|

DIAMETER |

DIAMETER |

MINIMUM |

MINIMUM |

TENSILE STRENGTH |

|

2,00 |

± 0,050 |

215 |

155 |

<500 |

|

2,20 |

± 0,060 |

230 |

170 |

<500 |

|

2,50 |

± 0,060 |

245 |

185 |

<500 |

|

2,70 |

± 0,060 |

245 |

185 |

<500 |

|

3,00 |

± 0,070 |

255 |

195 |

<500 |

|

3,90 |

± 0,070 |

275 |

220 |

<500 |

|

4,40 |

± 0,080 |

280 |

220 |

<500 |

|

5,00 |

± 0,080 |

280 |

220 |

<500 |

NOTE: Glozinc-Al wire might show difference in color or become darker with time. This does not affect the corrosion protection performance.