Insotherm WPU

Insotherm WPU panels cross section type Α

Insotherm WPU panels cross section type Α

Insotherm WPU panels cross section type Β

Insotherm WPU panels cross section type Β

Insotherm WPU panel joint detail

Insotherm WPU panel joint detail

The insulating Insotherm WPU panels of Kamaridis GlobalWire Group are complex, self-supporting structural elements, especially designed for sidewall cladding, construction of internal partitions and suspended ceilings.

The Insotherm WPU (PUR/PIR) panels consist of two formed metal sheets and insulation of self-extinguishing polyurethane resin.

The standardized metal sheets of the WPU panels are slightly formed from pre-painted galvanized steel in 0.30mm to 0.70mm-thick sheets with corrugations 50mm-wide and 1.5mm-deep at distances of 50mm.

The Insotherm WPU (PUR/PIR) panels are supported on the building shell via side-to-side fixing.

Characteristics

Natural characteristics

The foam is odorless, prevents the formation of mold and fungus, remains chemically neutral and the humidity does not change its mechanical capacities. Sensitive to the texture of the excessive sunlight and in contact with water only at the exposed surface as well.

Insotherm WPU panels cross section type Α

Insotherm WPU panels cross section type Α

Insotherm WPU panel joint

Insotherm WPU panel joint

Foam expansion

Pentane is used in foam expansion which is friendly to the atmosphere and to the environment in general as it is chlorofluorocarbons free (CFC & HCFC Free.)

Technical Data

|

TECHNICAL DATA INSOTHERM WPU PANELS |

||||

|

Thickness S |

Thermal K |

Polyurethane |

Panel Weight Steel Thickness |

|

|

mm |

Kcal/m2h°C |

Wm2K |

kg/m3 |

kg/m2 |

|

30 |

0,55 |

0,64 |

40+-2 |

9,66 |

|

40 |

0,43 |

0,50 |

40+-2 |

10,08 |

|

50 |

0,34 |

0,40 |

40+-2 |

10,50 |

|

60 |

0,29 |

0,34 |

40+-2 |

10,92 |

|

80 |

0,22 |

0,26 |

40+-2 |

11,76 |

*All calculations are theoretical based on the specific weight of Steel 7.85

|

PANEL THICKNESS APPLICATIONS |

||

|

APPLICATIONS |

THICKNESS |

THERMAL TRANSMITTANCE(Κ) |

|

Decorative/Suspended ceilings |

|

|

|

Min. Requirement |

30 |

|

|

Sporting Facilities |

40 |

0.53 |

|

Building Regulation Requirement |

50 |

0.43 |

|

Industrial air-conditioned Facilities |

60 |

0.36 |

|

Controlled Temperature Areas= °C |

80 |

0.28 |

|

Refrigeration -10°C |

100 |

0.23 |

|

Cooling Rooms -10°C |

120 |

0.18 |

|

Cooling Rooms -20°C |

140-160 |

0.16-0.15 |

|

Cooling Rooms -30°C |

180 |

0.13 |

|

Cooling Rooms -45°C |

200 |

0.11 |

|

Comparative Table of Insulation factors |

||||||||

|

Cork |

COMPRESSED WOOD |

WOOD |

CONCRETE |

BRICK |

COEFFICIENT THERMAL RESISTANCE |

COEFFICIENT THERMAL CONDUCTIVITY |

CONSUMPTION LITRES / PERIOD |

SAVINGS |

|

mm |

mm |

mm |

mm |

mm |

Rτ = m2.K/W |

U = W/m2.K |

PER m2 |

in lt / m2 yearly |

|

60 |

78 |

168 |

456 |

1032 |

1,37 |

0,73 |

7,33 |

3 |

|

80 |

104 |

224 |

608 |

1376 |

1,77 |

0,565 |

5,65 |

4 |

|

100 |

130 |

200 |

760 |

1720 |

2,17 |

0,461 |

4,61 |

5 |

|

120 |

156 |

336 |

912 |

2064 |

2,57 |

0,389 |

3,89 |

6 |

|

160 |

208 |

448 |

1216 |

2752 |

3,37 |

0,297 |

2,97 |

8 |

|

200 |

260 |

400 |

1520 |

3440 |

4,17 |

0,24 |

2,4 |

10 |

|

240 |

312 |

672 |

1824 |

4128 |

4,97 |

0,201 |

2,01 |

12 |

|

280 |

364 |

784 |

2128 |

4816 |

5,77 |

0,173 |

1,73 |

14 |

|

320 |

416 |

896 |

2432 |

5504 |

6,57 |

0,152 |

1,52 |

16 |

|

360 |

468 |

952 |

2736 |

6192 |

7,37 |

0,136 |

1,36 |

18 |

|

400 |

520 |

800 |

3040 |

6880 |

8,17 |

0,122 |

1,22 |

20 |

Technical data of steel (EN 10327 / EN 10142 / EN 10143)

Quality DX51D or S220, or S-250 or S-280 or S-320

Width 1.070mm / 1.070mm

Thickness 0.30mm – 0.70mm

Zinc 100-275 gr/m2

Tensile strength EN 10142

Technical paint data (SP)

|

Topcoat |

15-20 mic. |

|

Primer |

5 mic. |

|

Backcoat |

5-7 mic. |

Specifications of PVC coating

In most storage and food processing facilities, the use of PVC covering panels is required. PVC is available in two colors (RAL9002 & RAL9010) and in 120mic thickness. Both colors are certified and suitable for use in food storage and processing applications according to all European standards and regulations (78/142 / CEE, 80/766 / CEE, 82/711 / CEE, 85/572 / CEE, 90 / 128 / CEE, 92/39 / CEE).

For special paints or coatings such as PVDF and HD, please contact us.

Flexible Coating:

Aluminum sheet, kraft paper, paper aluminum, reinforced plasticized paper, tarpaper. Polyethylene paper, polyester

Polyurethane:

|

Density: |

40+-2 Kg/m3 (ISO 845) |

|

Thermal conductivity coefficient: |

λ=0,020 W/mK or λ=0,018 Kcal/mhºC at 10ºC (ASTM C 518) |

|

Crushing strength at 10% compression: |

0,22 N/mm2 (ISO 844) |

|

Adhesion: |

0,12 N/mm2 (ASTM D 162) |

|

Closed cells percentage: |

95-98% (ASTM D 285) |

|

Fire resistance: |

Β2/Β3 class (DIN 4102) |

|

Dimension stability: |

+-2 mm (ISO 2796) |

Dimensions:

Width (effective): 1.000mm

Length (upon request): 2.000mm – 15.500mm

Thickness: mm: 30 / 40 / 50 / 60 / 80 /100 / 120 / 140 / 160 / 180 / 200

Colours

Standard Colours

Note: The colors shown above may differ from those actually. The company is not responsible for any differences in shades due to display performance of each user.

Note: The colors shown above may differ from those actually. The company is not responsible for any differences in shades due to display performance of each user.

Additional Features

On customer demand and upon consultation concerning the minimum production quantities and the delivery deadlines, the Insotherm WPU panels can be also manufactured with plates of different hardness, thickness and type, such as prepainted aluminum, copper, stainless steel as well as with different coatings depending on the particular requirements of the project.

Loading Table

| Insotherm WPU panels Loading Table | |||||||||||||

| PANEL THICKNESS | METAL SHEET THICKNESS | |

|||||||||||

| SINGLE SPAN purling spacing (m) |

MULTIPLE SPAN purling spacing (m) |

||||||||||||

| 2,00 | 2,50 | 3,00 | 3,50 | 4,00 | 2,00 | 2,50 | 3,00 | 3,50 | 4,00 | 4,50 | 5,00 | ||

| S (mm) | t (mm) | MAXIMUM UNIFORMLY DISTRIBUTED LOAD CAPACITY IN daN/m2 | |||||||||||

| 30 | 0,50 / 0,50 | 147 | 78 | 194 | 122 | 73 | |||||||

| 0,60 / 0,60 | 158 | 84 | 53 | 211 | 131 | 78 | |||||||

| 40 | 0,50 / 0,50 | 196 | 140 | 93 | 57 | 294 | 186 | 127 | 90 | 64 | |||

| 0,60 / 0,60 | 211 | 150 | 100 | 61 | 306 | 201 | 136 | 96 | 69 | ||||

| 50 | 0,50 / 0,50 | 221 | 172 | 127 | 86 | 64 | 377 | 250 | 175 | 131 | 93 | 64 | |

| 0,60 / 0,60 | 235 | 183 | 136 | 92 | 69 | 392 | 274 | 188 | 141 | 100 | 69 | 53 | |

| 60 | 0,50 / 0,50 | 265 | 216 | 167 | 118 | 88 | 451 | 314 | 225 | 176 | 127 | 78 | 59 |

| 0,60 / 0,60 | 284 | 235 | 178 | 125 | 94 | 470 | 331 | 243 | 189 | 136 | 84 | 63 | |

| 80 | 0,50 / 0,50 | 343 | 245 | 186 | 147 | 118 | 554 | 426 | 319 | 237 | 181 | 137 | 113 |

| 0,60 / 0,60 | 363 | 265 | 206 | 158 | 125 | 569 | 443 | 336 | 260 | 194 | 147 | 121 | |

*The measurements have a coefficient f < L/200 and breaking point measurements have a protection coefficient 2.5.

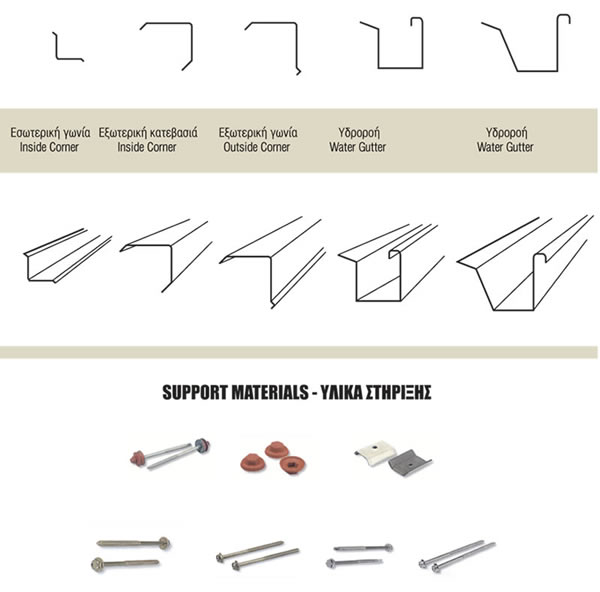

Seals - Support Materials - Special Items

For proper installation of the panels Insotherm WPU required a series of binders available from our company (Self screws, washers, gaskets). It recommends using 2.5 screws per m2.

For screws with greater captive capacity please contact us.

|

Panel Thickness |

Panel Thickness |

Panel Thickness |

|

30 |

6.3 x 50mm |

8mm |

|

40 |

6.3 x 60mm |

8mm |

|

50 |

6.3 x 70mm |

8mm |

|

60 |

6.3 x 80mm |

8mm |

|

80 |

6.3 x 100mm |

8mm |

|

100 |

6.3 x 120mm |

8mm |

After the installation of panels, it is necessary a number of special items for both sealing and for aesthetic completion of construction.

Each building has its own specific needs. Please contact our technical department in order to adapt the necessary items on your own construction.

Environment

The WPU coating system of our company is produced from materials friendly to the environment, (CFC free), characterized as ecological and not considered to be harmful.