EuroWool RW

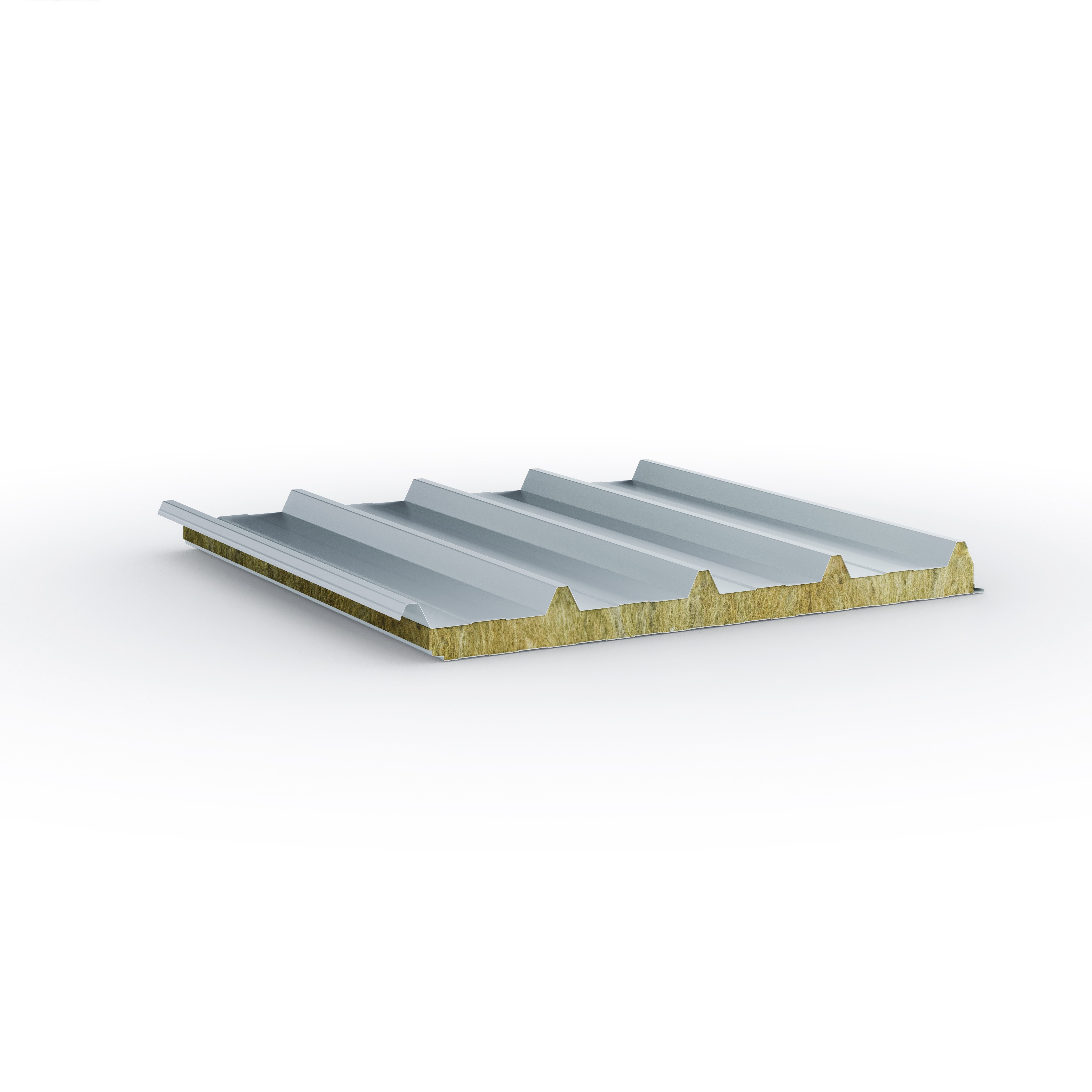

The rockwool roofing panels of Kamaridis GlobalWire Group, Econodeck RW, are composite, self-supported structural elements, specially designed for roofing coating. They are fire resistant structural elements with fire resistance indicator certified by ELOT and the Fire Service. The panels can be used in many other applications such as shelters, parkings, sports facilities, housings estates, prefabricated houses and many other constructions.

Characteristics

Natural characteristics

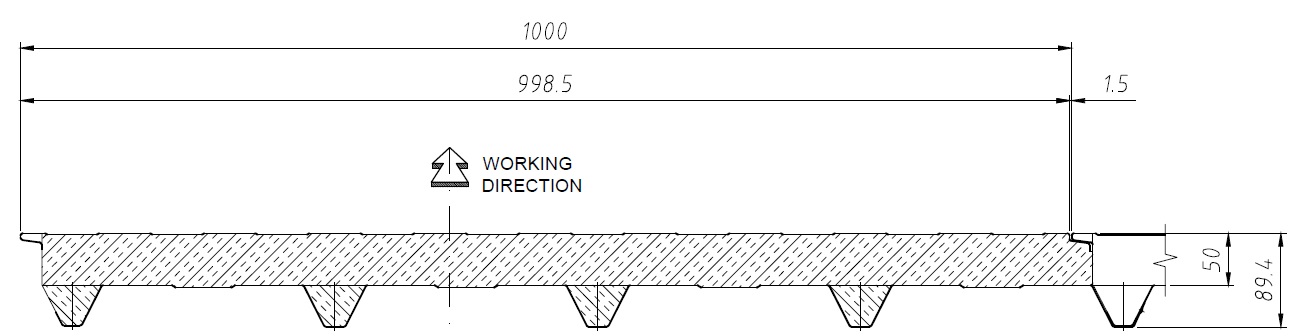

Eurowool RW cross-section

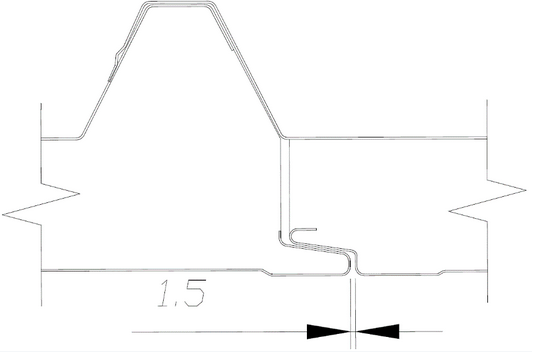

Eurowool RW joint detail

They consist of two slightly formed steel sheets and an intermediate insulating core of rock wool boards.

The panels are produced mostly by two shaped galvanized and pre-painted steel sheets, however there is the possibility to be produced in aluminum sheets, stainless steel, polyester, etc. The available lengths are from 2.00 to 15.50 meters. For smaller or larger lengths or any special requests please contact us.

The external metal sheet of the rockwool panels is trapezoidal (Ribdeck 1000), with five trapezoids 40mm-high at axial distances of 250mm.The internal metal sheet of the panels is slightly formed with corrugations of 1.5mm deep. These panels as recommended for use on roofs with pitches greater than 7%.

For pitches lower than 7% you should consult the technicians of our company.

The rockwool roofing panels can be combined with special double polyester transparent sheets that are easily integrated in manufacture and provide natural light in the monitored area, thus contributing significantly to energy savings

Rock wool was discovered in Hawaii in the beginning of the century and is derived from the resolidification process of molten lava that is thrown into the air during volcanic eruptions in fiber form.

Therefore, it s a totally natural product that combines the strength of the rock with the insulating features of wool.

Besides the fact that it is a completely natural product with high thermal insulation capacity, rock wool, thanks to the open cellular structure, it is an excellent sound-insulating material. It is the only material that manages to combine five key features.

Insulation

The presence of countless cells in the structure of rock wool allows the product to prevent the transit of heat and cooling and thus provides strong insulating results.

Sound insulation

The open cell structure of rockwool favors the absorption of acoustic waves and allows the reduction of intesity and the sound spread.

Excellent fire behavior

Rock wool is mainly an inorganic material that melts at temperatures above 1000 ° C. Therefore, they do not contribute to the development and spread of the fire and to the toxic gases emission as well.

Humidity Stability

Rock wool, due to its particular structure, does not absorb any water or humidity, so keeps its characteristics unchanged through time.

Dimensional stability

The rockwool conserves its characteristics in time and there are no changes in size or performance when the thermal and hygrometric environmental conditions change. Linear coefficient of thermal expansion of rock wool: 2x10-6C-1.

Technical Data

|

DIMENSIONAL TOLERANCES EN 14509 |

||

| THICKNESS |

±2mm |

D ≤ 100mm |

|

|

±2 % |

D > 100mm |

| LENGTH |

±5mm |

L ≤ 3000mm |

|

|

± 10mm |

L > 3000mm |

| WIDTH |

± 2mm |

W = 1000mm |

|

|

|

|

| FLATNESS |

≤ 0,6mm |

Li = 200mm |

|

|

≤ 1,00mm |

Li = 400mm |

|

|

≤ 1,50mm |

Li = 700mm |

|

|

|

|

| Longitudinalbowing (length) |

≤ 2mm |

Max 20mm |

| Camber(width) |

≤ 8,5 mm/m |

H ≤ 10mm |

|

|

≤ 10 mm/m |

H > 10mm |

|

Thickness |

Thermal Transmittance |

FireResistance |

|||

|

Mm |

W / m2K |

R |

E |

I |

Classification |

|

50 |

0,63 |

120 |

120 |

30 |

REI30 – RE 120 |

|

60 |

0,53 |

180 |

180 |

85 |

REI 60 – RE 180 |

|

80 |

0,40 |

220 |

220 |

130 |

REI 120 – RE 180 |

|

100 |

0,32 |

221 |

221 |

157 |

REI 120 – RE 180 |

|

120 |

0,27 |

236 |

236 |

184 |

REI 180 |

|

150 |

0,22 |

257 |

257 |

225 |

REI 180 - RE 240 |

|

200 |

0,17 |

292 |

292 |

290 |

REI 240 |

The U-factor has been calculated with thermal conductivity λ = 0,033 W / mK

Materials

Rockwool: density 100kg/m³ or 120kg/m³.

Technical data of steel (EN 10327 / EN 10142 / EN 10143)

|

Quality |

DX51D or S-220 or S-250 or S-280 orS-320 |

|

Width |

1.250mm / 1.070mm |

|

Thickness |

0.30mm – 0.70mm |

|

Zinc |

100-275 gr/m2 |

|

Tensile strength |

EN 10142 |

Technical paint data (SP)

|

Topcoat |

15-20 mic. |

|

Primer |

5 mic. |

|

Backcoat |

5-7 mic. |

Specifications of PVC coating

In most storage and food processing facilities, the use of PVC covering panels is required. PVC is available in two colors (RAL9002 & RAL9010) and in 120mic thickness. Both colors are certified and suitable for use in food storage and processing applications according to all European standards and regulations (78/142 / CEE, 80/766 / CEE, 82/711 / CEE, 85/572 / CEE, 90 / 128 / CEE, 92/39 / CEE).

For special paints or coatings such as PVDF and HD, please contact us.

Dimensions

Width (effective): 1.000mm

Length (upon request): 2.000mm – 15.500mm

Thickness: mm: 50 / 60 / 80 /100 / 150

Colors

Standard colors:

Note: The colors shown above may differ from those actually. The company is not responsible for any differences in shades due to display performance of each user.

Note: The colors shown above may differ from those actually. The company is not responsible for any differences in shades due to display performance of each user.

Additional Features

On customer demand and upon consultation concerning the minimum production quantities and the delivery deadlines, the rockwool roof panels Econodeck can be also manufactured with plates of different hardness, thickness and type, such as prepainted aluminum, copper, PVC, stainless steel as well as with different coatings depending on the particular requirements of the project.

Loading Table

|

THICKNESS S Mm |

WEIGHT Kg/m2 |

MULTIPLEPOINTS

Max loadcapacity |

||||||||

|

DaN/m2 |

80 |

100 |

120 |

150 |

200 |

250 |

300 |

|||

|

50 |

14.82 |

ΜΕΓΙΣΤΑ ΕΠΙΤΡΕΠΟΜΕΝΑ ΝΟΙΓΜΑΤΑm |

L = |

3.30 |

2.90 |

2.50 |

2.20 |

1.70 |

1.35 |

1.10 |

|

60 |

15.82 |

L = |

3.70 |

3.20 |

3.00 |

2.60 |

1.90 |

1.65 |

1.30 |

|

|

80 |

17.82 |

L = |

4.40 |

3.90 |

3.60 |

3.05 |

2.27 |

1.90 |

1.50 |

|

|

100 |

19.82 |

L = |

4.80 |

4.30 |

3.90 |

3.20 |

2.45 |

2.08 |

1.60 |

|

|

120 |

21.82 |

L = |

5.20 |

4.60 |

4,10 |

3,45 |

2,65 |

2,18 |

1,80 |

|

|

150 |

24.82 |

L = |

5.50 |

4.80 |

4.35 |

3.62 |

2.85 |

2.32 |

2.00 |

|

|

200 |

29.82 |

L = |

6.10 |

5.05 |

4.58 |

3.80 |

3.20 |

2.70 |

2.10 |

|

|

THICKNESS S Mm |

WEIGHT Kg/m2 |

SimpleSpan

Max loadcapacity |

||||||||

|

DaN/m2 |

80 |

100 |

120 |

150 |

200 |

250 |

300 |

|||

|

50 |

14.82 |

ΜΕΓΙΣΤΑ ΕΠΙΤΡΕΠΟΜΕΝΑ ΝΟΙΓΜΑΤΑm |

L = |

3,00 |

2,65 |

2,30 |

1,90 |

1,50 |

1,20 |

1,00 |

|

60 |

15.82 |

L = |

3,40 |

3,00 |

2,70 |

2,50 |

1,60 |

1,50 |

1,18 |

|

|

80 |

17.82 |

L = |

4,10 |

3,65 |

3,20 |

2,70 |

2,10 |

1,59 |

1,30 |

|

|

100 |

19.82 |

L = |

4,50 |

4,00 |

3,50 |

2,90 |

2,19 |

1,80 |

1,40 |

|

|

120 |

21.82 |

L = |

4,90 |

4,35 |

3,70 |

3,10 |

2,40 |

1,90 |

1,55 |

|

|

150 |

24.82 |

L = |

5,10 |

4,50 |

3,89 |

3,30 |

2,59 |

2,20 |

1,70 |

|

|

200 |

29.82 |

L = |

5,40 |

4,70 |

4,25 |

3,58 |

2,94 |

2,48 |

2,00 |

|

- elastic deflection ≤l / 200

- Density 100 Kgr / m2

- sheetthicknesse 050mm / 050mm

- Quality of Steel DX 51 D

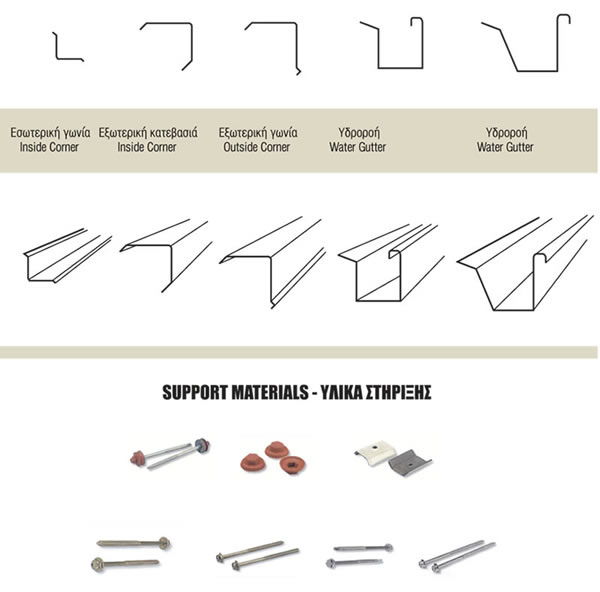

Seals - Support Materials - Special Items

For proper installation of the rock wool roof panels required a series of binders available from our company (Self screws, washers, gaskets).

The use of 2.5 screws per m2. Is recommended.

For screws with greater captive capacity please contact us.

|

Panel Thickness |

Screw type |

Captive capacity |

|

30 |

5.5 x 120mm |

8mm |

|

40 |

5.5 x 120mm |

8mm |

|

50 |

5.5 x 130mm |

8mm |

|

60 |

5.5 x 150mm |

8mm |

|

80 |

6.3 x 150mm |

8mm |

|

100 |

6.3 x 170mm |

8mm |

After the installation of panels, it is necessary a number of special items for both sealing and for aesthetic completion of construction.

Each building has its own specific needs.

Please contact our technical department in order to adapt the necessary special items on your own construction.

Environment

The rock wool roof panels coating system of our company is produced from materials friendly to the environment, (CFC free), characterized as ecological and not considered to be harmful.